| Size | 2 “ - 48 ” |

| Pressure | ANSI 150LB-2500LB |

| End Connection | Flange RF,RTJ,BW |

| Bore | Full or Reduce Bore |

| Body Material | ASTM A105,F304 F316 ,F304L,F316L,LF2 ,F51,F53,GR.4A,GR.5A,and ETC |

| Ball Material | A105+ENP,13CR, A351 CF8(A182 F304),A351CF8M(A182 F316) ,ETC |

| Seat Material | PTFE, RPTFE, PEEK,NYLON,PPL Or metal to metal |

| Design | API 6D/ ASME B16.34 |

| Face to Face | ANSI B16.10 |

| End Flange | ANSI B16.5 |

| BW Ends | ANSI B16.25 |

| Fire Safe | API 607 Or API6FA |

| Checking & Test | API 598 |

| Pressure-Temperature | ASME B16.34 |

| Operation | By Lever, By Gear, By Electric or Pneumatic Actuator |

Features

?Two Piece or Three Piece bolted Body and Cap?Full or Reduce Bore

?High Performance Sealing Mechanism

?Fire Safety Design

?Anti-Static Spring Device

?Blow-out proof stem

?Low Emission Design

?Double Block and Bleed function

?Locking Device for Lever Operation

?Low Operation Torque

?Self-relief of Excessive Cavity Pressure

?Packing with live loaded sealing mechanism

Material Specification

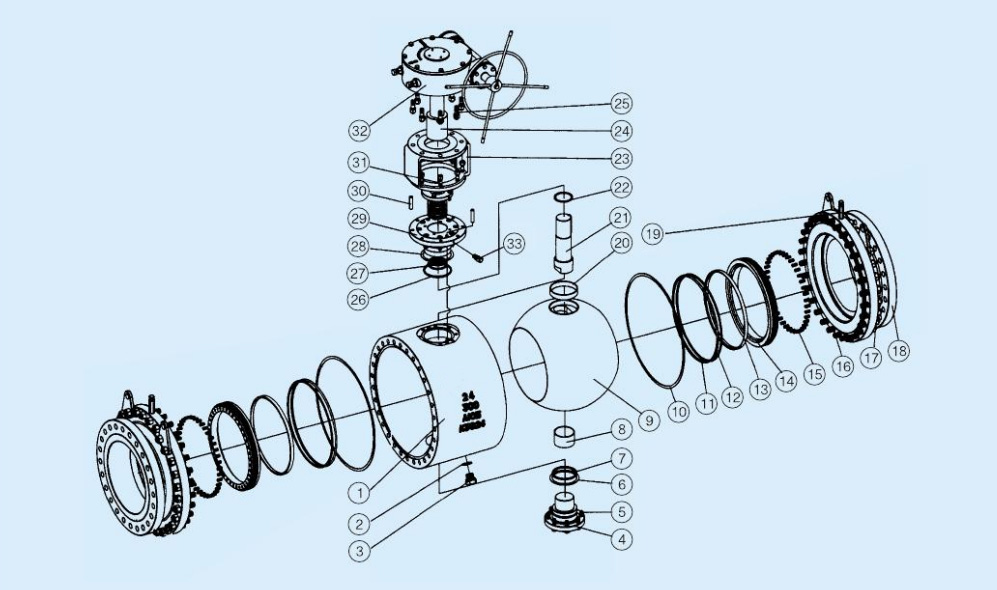

| No. | Name | Material | No. | Name | Material |

| 1 | Body | A105/F304/LF2 | 18 | Cap | A105/F304/LF2 |

| 2 | Gasket | Graphite+SS | 19 | Grease Valve | A105/F304/LF2 |

| 3 | Drain valve | A105/F304/LF2 | 20 | Bushing | PTFE+CS/PTFE+SS |

| 4 | Bottom Cover | A105/F304/LF2 | 21 | Stem | A182 F6a/F304 |

| 5 | Bolt | A193 B7/B8/L7 | 22 | Bushing | PTFE+CS/PTFE+SS |

| 6 | Gasket | Graphite+SS | 23 | Yoke | A216 WCB |

| 7 | O-Ring | Viton | 24 | Sleeve | ANSI 1025 |

| 8 | Bushing | PTFE+SS | 25 | Bolt | A193 B7 |

| 9 | Ball | A105+ENP/F304 | 26 | O-Ring | Viton |

| 10 | Gasket | Graphite+SS | 27 | O-Ring | Viton |

| 11 | O-Ring | Viton | 28 | Gasket | Graphite+SS |

| 12 | Fire Ring | Graphite | 29 | Bonnet | A105/F304/LF2 |

| 13 | Seat Sealing | PTFE,PEEK,NYLON | 30 | Pin | A182 F6a |

| 14 | Seat | A105+ENP/F304 | 31 | Bolt | A193 B7 |

| 15 | Spring | Inconel 600 | 32 | Gear | / |

| 16 | Bolt | A193 B7/B8/L7 | 33 | Grease Valve | A105/F304/LF2 |

| 17 | Nut | A194 2H/8/7 | |

Advantages

1.Forged Body2.Pressure relief valve to avoid cavity over pressure when applicable

3.Emergency built-in stem and seat sealant injection system

4.DBB design enables the use of a single valve with two independently functioning seats on each end of the valve while allowing the cavity between the seating surfaces to be vented or bled.

Other Information

| Payment Term | L/C, T/T, Western Union,Paypal |

| Delivery Time | 15 - 30 days after payment |

| Seaport | Shanghai Or Ningbo China |

| The 3rd Inspection | Available |

| Sample | Available for API 6D Trunnion Mounted Ball Valve |

| Warranty Period | 18 months after shipments and 12 months after installed |

| Valve Test | 100% quantity tested before delivery |

| Packing | Plywood Case for API 6D Trunnion Mounted Ball Valve |

| MOQ | 1 Pc for API 6D Trunnion Mounted Ball Valve |

| Nameplate | According to customer for API 6D Trunnion Mounted Ball Valve |

| Color | According to customer for API 6D Trunnion Mounted Ball Valve |

| Shipment | By sea,By Air ,By Express,and door to door available |

| OEM/ODM Service | Available |